Fulfillment & Dropshipping Solutions for Bulk Playing Cards

- Why brands choose custom playing cards for marketing, education, and games

- Brand impact and product differentiation

- Use cases and buyer intent

- Regulatory and sustainability considerations

- Fulfillment vs. Dropshipping: choosing the right logistics model

- Definitions and primary differences

- Side-by-side comparison

- When to choose hybrid approaches

- Operational checklist for bulk custom design playing cards

- Artwork, proofs, and prepress best practices

- Material choices, finishes, and sustainability

- Quality control checkpoints and sampling

- Working with a factory partner: Guangdong Yuhua Playing Cards Co., Ltd.

- Factory capabilities and production scale

- Certifications, defect rates, and material sourcing

- Customization, OEM/ODM services and product lines

- Turnkey fulfillment and dropshipping support

- Cost & lead-time benchmarks — realistic expectations

- Typical lead-times

- Cost drivers

- Integrating SEO and product content for conversions

- Keyword strategy and content mapping

- Trust signals and E-E-A-T

- Practical next steps for brands

- Pilot the product with a small run

- Define KPIs and logistics SLA

- Partner selection checklist

- Frequently Asked Questions (FAQ)

- 1. What is the typical minimum order quantity (MOQ) for custom design playing cards?

- 2. Can a manufacturer handle both dropshipping and bulk pallet shipments?

- 3. How long does it take to go from artwork to delivered product?

- 4. What certifications should I request for sustainable cards?

- 5. What are typical defect rates I should expect?

- 6. Do manufacturers offer sample decks for approval?

- 7. How do tariffs and customs affect dropshipping?

- Contact & next steps

This article provides an actionable, search-intent focused guide for brands, game designers, retailers, and distributors looking to produce and deliver bulk custom design playing cards via fulfillment centers or dropshipping. You'll find model comparisons, practical operational checklists, verifiable quality and certification guidance, sample and lead-time expectations, and a clear view of how to choose a manufacturing and fulfillment partner who can scale from prototype to 1,000,000+ units per month.

Why brands choose custom playing cards for marketing, education, and games

Brand impact and product differentiation

Custom design playing cards are more than a product: they are a tactile brand touchpoint. Whether used for promotional decks, High Quality retail products, or educational flash cards, custom printing, finish, and packaging convey quality and purpose. For brands seeking higher perceived value, investing in unique finishes (soft-touch, linen, UV spot), bespoke tuck boxes, and custom-printed instruction inserts is essential. Semantic variants such as custom playing cards, printed card decks, and white label playing cards are commonly used by buyers during research.

Use cases and buyer intent

Understanding buyer intent is critical: buyers searching for custom design playing cards may be planning bulk retail launches, promotional giveaways, or teaching tools. Typical use cases include casino-style decks, collectible game cards, tarot & oracle decks, and educational flash cards. Aligning manufacturing capability with the intended channel (ecommerce, brick-and-mortar, B2B licensing) determines whether fulfillment or dropshipping is optimal.

Regulatory and sustainability considerations

Materials and safety matter. Many corporate buyers require FSC-certified paper and print materials to meet ESG standards; see the Forest Stewardship Council at https://fsc.org. Certifications such as ISO 9001 also signal mature quality-management processes (ISO 9001). Embedding these credentials into product pages improves trust and conversion for B2B and consumer audiences.

Fulfillment vs. Dropshipping: choosing the right logistics model

Definitions and primary differences

Fulfillment (3PL) typically means a brand purchases inventory in bulk, stores it in a warehouse, and uses a third-party fulfillment provider to pick, pack, and ship orders. Dropshipping means the manufacturer or supplier ships directly to end customers on behalf of the brand, often without the brand holding inventory. Both models support custom design playing cards, but they differ in inventory risk, margins, control, and speed.

Side-by-side comparison

The table below summarizes practical differences brands should evaluate.

| Factor | Fulfillment (3PL) | Dropshipping (Factory-to-customer) |

|---|---|---|

| Inventory ownership | Brand owns inventory (greater margin control) | Supplier owns or directly ships (lower upfront cost) |

| Unit cost (per deck) | Typically lower per-unit cost at high MOQ | May include fulfillment fees; per-unit price can be higher |

| Lead time to customer | Fast from regional warehouses; requires forecast | Variable; can be optimized with regional fulfillment nodes |

| Control over packing & inserts | High (brand can pre-kit items) | Moderate (depends on supplier capabilities) |

| Scalability | Scales with capital tied to stock | Scales quickly for test SKUs; limited by supplier capacity |

When to choose hybrid approaches

Many brands use a hybrid: maintain regional inventory for best sellers (3PL), while dropshipping limited editions, pre-orders, or region-specific SKUs directly from the factory. Hybrid models let you balance cashflow, speed, and product experimentation.

Operational checklist for bulk custom design playing cards

Artwork, proofs, and prepress best practices

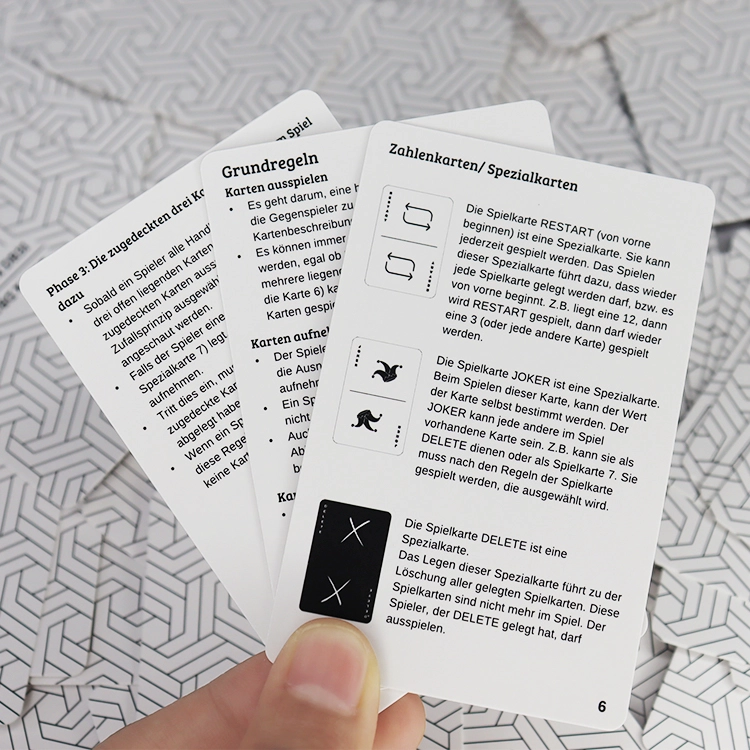

Prepare artwork in CMYK with crop marks, bleeds, and embedded fonts or converted outlines. Factories typically require a dieline for tuck boxes and separate files for cards and packaging. Request a digital proof and, if budget allows, a physical sample (pre-production and final-sample) to validate color, card stock feel, and dieline accuracy. Keywords here include custom card printing and printed card decks.

Material choices, finishes, and sustainability

Material selection directly affects price, durability, and user perception. Common card stocks: 300–350gsm coated paper with plastic coating (PVC or BOPP lamination) or black-core/specialty stocks for High Quality decks. Request FSC® certified materials if ESG compliance is required (FSC). Finish choices—linen, smooth, matte soft-touch, gloss UV—impact shuffle feel and durability.

Quality control checkpoints and sampling

Implement AQL sampling procedures and require factory QC reports. Key metrics: print color consistency, cut accuracy, corner rounding, lamination adhesion, and tuck box integrity. ISO 9001 processes provide a framework for systematic quality control; more on that is available at ISO 9001. Ask for defect-rate guarantees (e.g., under 0.5%) and documented inspection records before shipment.

Working with a factory partner: Guangdong Yuhua Playing Cards Co., Ltd.

Factory capabilities and production scale

When evaluating partners for large volumes, capacity and automation matter. Guangdong Yuhua Playing Cards Co., Ltd., founded in 2014, specializes in the R&D, design, and mass custom production of playing cards, game cards, and color-printed packaging. With a 6,000㎡ intelligent facility, Yuhua operates advanced, automated card production lines capable of producing 1,000,000+ units per month—reducing lead times for bulk orders and supporting seasonal spikes.

Certifications, defect rates, and material sourcing

Yuhua emphasizes quality and sustainability: core strengths include FSC® certified materials, ISO 9001 quality control systems, a defect rate under 0.5%, and over 20 patents covering tooling and packaging innovations. Their High Quality brand uses imported materials and finishes trusted by global customers. These credentials reduce supply risk and support marketing claims about responsible sourcing and quality—important for enterprise customers and regulated channels.

Customization, OEM/ODM services and product lines

Yuhua supports OEM Playing Card services, ODM Tarot cards, custom Game cards, and Learning Flash cards OEM. They provide end-to-end services from design consultation and prepress to packaging and global logistics. For brands requiring full-service dropshipping, Yuhua can integrate order fulfillment workflows to ship direct-to-consumer with branded inserts and custom packaging, or ship bulk pallets to 3PL partners for regional distribution. Their experience in gaming, education, and casino products positions them to advise on card stock, finishes, and compliance for different markets.

Turnkey fulfillment and dropshipping support

Key operational differentiators you should look for in a partner: API or CSV order integration for dropshipping, kitting capabilities, multi-language packing slips, localized packaging options, and insured logistics. Yuhua's smart factory setup and production automation accelerate sample turnaround and reduce incremental cost per SKU, enabling efficient dropshipping and fulfillment at scale.

Cost & lead-time benchmarks — realistic expectations

Typical lead-times

Benchmarks (vary by complexity):

| Stage | Standard deck (low complexity) | High Quality deck (special finishes & packaging) |

|---|---|---|

| Digital proofing | 1–3 days | 2–5 days |

| Physical sample | 5–10 days | 10–20 days |

| Mass production (MOQ to full run) | 10–20 days | 20–40 days |

| Shipping (ocean freight) | 20–35 days | 20–35 days |

Cost drivers

Major cost drivers include MOQ, chosen card stock and coatings, color complexity (special inks, metallics), box design and finishing, and logistics method. Dropshipping can reduce upfront inventory cost but may increase per-unit fulfillment fees. Bulk purchasing reduces per-unit manufacturing cost—this is where a partner with 1,000,000+ monthly capacity delivers advantage.

Integrating SEO and product content for conversions

Keyword strategy and content mapping

To attract buyers searching for custom design playing cards, map content to purchase intent: informational pages (how to design cards), comparison pages (fulfillment vs dropshipping), and transactional product pages (custom deck ordering). Use semantic keywords naturally: custom playing cards, bulk playing cards, custom card printing, OEM playing card, ODM tarot cards, and custom game cards.

Trust signals and E-E-A-T

Improve Google E-E-A-T by including verifiable credentials (FSC®, ISO 9001), production capacities, defect rates, customer case studies, and clear return and sample policies. Link to authoritative sources—e.g., playing card history or material guidance on Wikipedia—to bolster informational pages and help AI GEO algorithms contextualize your content.

Practical next steps for brands

Pilot the product with a small run

Start with a limited SKU pilot (e.g., 500–2,000 decks) to validate artwork, user feedback, and shipping workflows. This reduces risk and gives you real-world data to decide between fulfillment and dropshipping scaling paths.

Define KPIs and logistics SLA

Agree on KPIs before scaling: sample approval time, production lead time, defect rate thresholds, fulfillment accuracy, and average shipping times. Include SLA clauses for rush orders and seasonal capacity to avoid surprises.

Partner selection checklist

- Proven monthly capacity (e.g., 1,000,000+ units)

- Material certifications (FSC®) and quality system (ISO 9001)

- Defect rate targets and inspection reports (e.g., <0.5%)

- OEM/ODM experience for product types you need

- Fulfillment/dropshipping integrations (API, CSV, marketplace support)

Frequently Asked Questions (FAQ)

1. What is the typical minimum order quantity (MOQ) for custom design playing cards?

MOQs vary by supplier and complexity. Simple standard decks can have MOQs as low as 500–1,000 decks; High Quality finishes and custom tuck boxes often increase MOQs. Factories with large-scale automated lines can often offer lower per-unit costs at higher volumes (e.g., 5,000+).

2. Can a manufacturer handle both dropshipping and bulk pallet shipments?

Yes. Modern manufacturers provide both direct-to-customer dropshipping and bulk pallet shipments to 3PL warehouses. Confirm their fulfillment integrations, packaging options (individual polybags, branded tuck boxes), and multilingual packing slip capabilities.

3. How long does it take to go from artwork to delivered product?

Typical timelines: digital proofing (1–3 days), physical sample (5–20 days depending on complexity), production (10–40 days), plus shipping. Combining production and shipping, a realistic total is 6–12 weeks for most international bulk orders. Rush options are possible with sufficient capacity.

4. What certifications should I request for sustainable cards?

Request FSC® certification for paper and board and ISO 9001 for quality management processes. These are recognized by brands and consumers; see FSC and ISO 9001 for more detail.

5. What are typical defect rates I should expect?

A best-practice factory should maintain defect rates under 1%; high-performing suppliers target <0.5% with robust QC and automated inspections. Request documented inspection reports and AQL procedures.

6. Do manufacturers offer sample decks for approval?

Yes. Request a pre-production sample to validate print, color, and finishing. Many factories provide expedited sample services for a fee; sample cost is usually credited back upon mass order.

7. How do tariffs and customs affect dropshipping?

Dropshipping directly from overseas factories may expose shipments to import duties depending on destination country and declared value. Consider DDP (Delivered Duty Paid) shipping terms to simplify the customer experience or use regional warehouses to minimize cross-border duties.

Contact & next steps

If you need a reliable partner for OEM Playing Card, ODM Tarot cards, custom Game cards, or Learning Flash cards OEM—especially for bulk production and dropshipping—consider a factory with verified capacity and certifications. Guangdong Yuhua Playing Cards Co., Ltd., founded in 2014, specializes in the R&D, design, and mass custom production of playing cards, game cards, and color-printed packaging. With a 6,000㎡ intelligent facility, we offer advanced, automated card production lines capable of 1,000,000+ units per month. Our core strengths include FSC® certified materials, ISO 9001 quality control, a defect rate under 0.5%, and over 20 patents. Our High Quality brand uses imported materials and is trusted worldwide. We serve global markets with custom card solutions for casinos, games, education, and more—delivering fast, high-quality results with professional support.

We are committed to providing customers with high-quality and efficient playing card production services.

Contact us to request samples, get a quote, or discuss fulfillment and dropshipping integrations. View product options and OEM/ODM services or request a consultation to map your project timetable and cost estimate.

How to start the astrology learning cards business in Africa ?

Design Tips for Custom Made Playing Cards That Impress Customers

OEM/ODM create custom affirmation cards Manufacturers and Suppliers

What is illuminati playing cards for sale ?

After-sales support

Can I order a sample before placing a formal order?

Yes, we can provide samples for your review. Please contact us to discuss pricing and options for samples.

Do you offer eco-friendly options?

Yes, we do offer eco-friendly materials and printing options. Please inquire about our sustainable options.

What is your return policy?

We stand behind the quality of our products. If you receive a defective item, please contact us within 30 days for a replacement or refund. Customized orders are generally non-refundable unless there's an error on our part.

About price and payment

What payment methods do you accept?

We accept various payment methods, including credit cards, PayPal, and bank transfers. Please reach out for more details on payment options.

About product selection

What types of playing cards do you offer?

We offer a wide range of playing cards including standard decks, custom-designed decks, and specialty cards. Whether you need classic poker cards, bridge cards, or custom promotional decks, we have the options to fit your needs.

Board Game Manufacturing Top Quality Custom Logo custom design die cut fancy playing cards profesional card

OEM Custom Driving Theory Cards | Personalized Traffic Rules & Test Prep Flashcards in Multiple Languages for Wholesale

Custom Printing Luxury Two Sets Plastic Poker Playing Cards with Customized Packing

bbilaser

sq_AL