Quality Control Checklist for Custom Playing Card Suppliers

- Comprehensive QC Framework for Custom Playing Cards

- Key quality dimensions

- How QC aligns with customer requirements

- Pre-production Quality Checks

- Artwork and proofing standards

- Material validation: paper, ink, coatings

- Production-stage Quality Controls

- Printing & color consistency

- Cutting, coating, and finish controls

- Post-production Inspection & Packaging

- Sampling, AQL, and defect classification

- Packaging, labeling, storage & shipping checks

- Performance Testing, Traceability & Continuous Improvement

- Durability and lifecycle tests

- Traceability, batch records, and corrective actions

- Practical Checklist (Printable Table)

- Common Defect Types & Remediation Strategies

- Color inconsistency

- Miscut or uneven corner radius

- Coating defects (orange peel, adhesive failure)

- Supplier Selection and Audit Checklist

- Factory capabilities & certification

- References, lead time & scalability

- FAQ — Frequently Asked Questions

- 1. What is the recommended AQL for custom playing cards?

- 2. How do I ensure color accuracy for custom designs?

- 3. Which card stock is best for High Quality decks?

- 4. Should I require third-party inspection?

- 5. How do I handle color differences between batches?

- 6. What packaging checks are essential for export?

- Contact & Next Steps

- References

High-quality custom design playing cards require a consistent, verifiable quality control system that spans artwork approval, material selection, production processes, sampling, and shipment. This guide provides a location-aware, production-ready QC checklist suitable for suppliers serving local and international markets—helping OEMs, print buyers, and brand owners minimize returns and protect reputation across China, Europe, and North America.

Comprehensive QC Framework for Custom Playing Cards

Key quality dimensions

Quality for custom design playing cards is multidimensional: material integrity (paperboard weight, fiber content, and coatings), print fidelity (color accuracy, registration, dot gain), mechanical performance (cut, corner roundness, handling, shuffle feel), and durability (coating adhesion, abrasion resistance). Objective metrics and documented acceptance criteria transform subjective expectations (feels High Quality) into measurable targets.

How QC aligns with customer requirements

Define a written Quality Agreement before production. The agreement should include: product specification (card weight/gsm, number of cards, tuck box type), color targets (PANTONE or CMYK values), acceptable tolerances for dimensions and defects, sampling plans (AQL), packaging and labeling, lead times, and remediation steps for nonconformities. Use visual references—digital proofs and physical pre-production samples—signed off by the buyer.

Pre-production Quality Checks

Artwork and proofing standards

Checklist items:

- File format and resolution: Vector for line art; 300–600 dpi for raster. Embed fonts or convert to outlines.

- Bleed and trim: Minimum 3mm bleed beyond cut lines; safe zone of 3–5 mm inside trim for critical elements.

- Color management: Provide PANTONE swatches or ICC profiles. Request a contract proof (digital or physical) and a press check approval before bulk run.

Maintain a proof archive (digital timestamps and image files) to resolve disputes and for ongoing process improvements.

Material validation: paper, ink, coatings

Key materials and their checks:

- Paperboard: Verify grammage (e.g., 300–420 gsm for playing card sets), thickness (mm), stiffness, and moisture content. Request a certificate of conformity and sample with lot number.

- Inks: Check compatibility with coating/lamination; test for migration and drying time. For food-contact concerns (e.g., children’s products), ensure compliant inks.

- Coatings & finishes: Choose between aqueous varnish, UV varnish, soft-touch lamination, or traditional varnish. Each affects durability and tactile feel—require finish samples.

Production-stage Quality Controls

Printing & color consistency

Implement in-line and end-of-shift checks:

- First-article inspection (FAI): Compare the first few prints to approved proof; verify color, registration, and image clarity.

- Control charts: Track color density and dot gain using a densitometer; maintain SPC (statistical process control) charts for key color patches.

- Press checks: Use standardized lighting (D50) and viewing booth for color approval.

Cutting, coating, and finish controls

Critical mechanical checks:

- Cut accuracy and deck alignment: Tolerance typically ±0.5 mm for card faces; corner radius consistency across deck.

- Coating uniformity: Test adhesion (cross-hatch test), surface friction, and gloss level using a gloss meter where specified.

- Shuffle & snap tests: Randomly sample decks for handling tests to evaluate edge-rounding, friction, and stiffness.

Post-production Inspection & Packaging

Sampling, AQL, and defect classification

Adopt a statistically valid sampling method. ANSI/ASQ Z1.4 is commonly used for lot-by-lot acceptance sampling; it defines Acceptable Quality Limits (AQL) and sample sizes depending on lot size and inspection level. For consumer-grade playing cards, common AQLs are:

| Defect Type | Severity | Typical AQL Target |

|---|---|---|

| Visual printing errors (misprint, smudge) | Major | 0.65%–1.5% |

| Dimension / cut errors | Major | 0.65%–1.5% |

| Minor cosmetic issues (ink speck, slight scratch) | Minor | 2.5%–4% (varies by buyer tolerance) |

Use an independent inspection provider for first shipments or high-volume orders. Classify defects as Critical (safety/legal), Major (function/appearance), or Minor (cosmetic).

Packaging, labeling, storage & shipping checks

Packaging must protect decks from moisture, crushing, and color transfer. Checklist:

- Inner wrap: Polybags, cello sleeve, or inner tuck depending on packaging spec; sealed and numbered by lot.

- Tuck box & outer cartons: Check for structure integrity, print match, and correct barcodes/labels.

- Palletization: Follow recommended stacking height, corner protection, and moisture barriers for sea shipments.

Performance Testing, Traceability & Continuous Improvement

Durability and lifecycle tests

Run accelerated wear tests to evaluate long-term handling:

- Abrasion tests: Simulate shuffle cycles with abrasion testers to estimate durability.

- Coating adhesion and cracking: Use bend tests and humidity cycles to reveal delamination risks.

- Colorfastness: Test for rub resistance and lightfastness using standardized tests where applicable.

Traceability, batch records, and corrective actions

Maintain lot-level traceability: raw material lot numbers, machine settings, operator signatures, and inspection records. When a nonconformity arises, apply a standardized CAPA process (Corrective and Preventive Action): contain the issue, investigate root cause (5 Whys or fishbone), implement correction, and verify effectiveness. Document all steps and update the Quality Agreement if necessary.

Practical Checklist (Printable Table)

Use this condensed checklist to run routine inspections or integrate into an ERP/QMS system.

| Stage | Checkpoint | Method / Tool | Acceptance Criteria |

|---|---|---|---|

| Pre-production | Artwork approval | Signed proof | Signed by buyer |

| Materials | Paperboard spec | GSM scale, COA | Matches agreed GSM & COA |

| Printing | Color match | Densitometer, visual booth | Within Delta E or densitometry tolerance |

| Finishing | Coating adhesion | Cross-hatch test | No delamination |

| Cutting | Dimension & corner radius | Caliper, gauge | Within ±0.5 mm |

| Final | Sampling & AQL | ANSI/ASQ Z1.4 | Pass sample plan |

| Packaging | Carton & labeling | Visual & barcode scanner | Correct label, undamaged cartons |

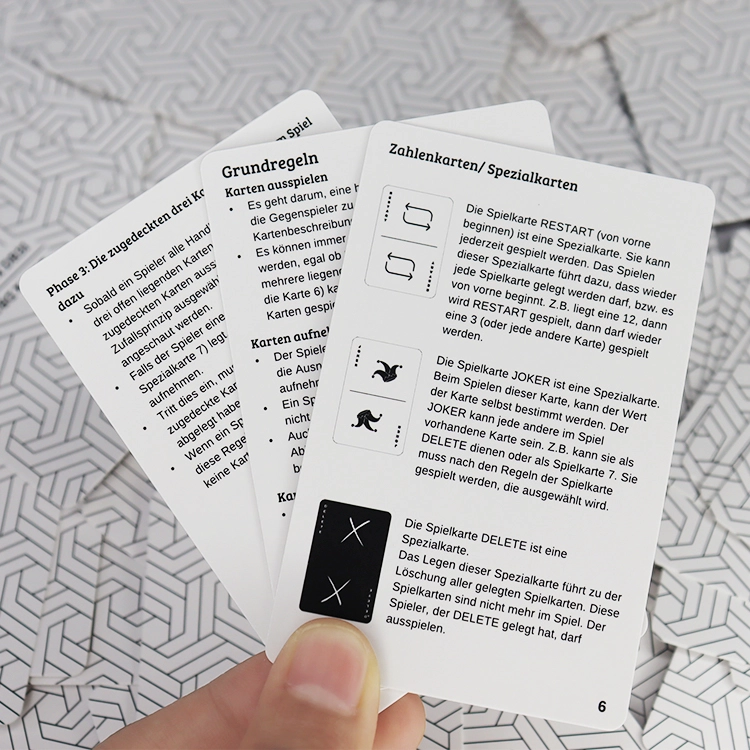

Common Defect Types & Remediation Strategies

Color inconsistency

Cause: press setup, ink batch variation, or humidity. Remediation: halt the press, recalibrate ink keys, record the batch that failed, segregate affected decks, and reprint if necessary. Maintain color targets with ICC profiles and a press fingerprint file for each job.

Miscut or uneven corner radius

Cause: worn cutting dies or misaligned guillotines. Remediation: inspect die for wear, recalibrate cutting equipment, and perform 100% inspection for edge-critical items if the issue is found mid-run.

Coating defects (orange peel, adhesive failure)

Cause: incorrect coating thickness, incompatible ink/coat chemistry, or curing problems. Remediation: run adhesion and drying tests on sample boards, adjust coat weight, and validate a compatible ink/coat combination before restarting.

Supplier Selection and Audit Checklist

Factory capabilities & certification

Ask for documentation: ISO 9001 certification demonstrates a quality management system; FSC chain-of-custody for sustainable paper; local safety approvals if the cards are for children. Factory tour and sample review are essential.

References, lead time & scalability

Obtain references from other brands, recent sample galleries, and typical lead times for small-batch and mass production. Confirm the supplier’s ability to scale while maintaining QC via documented processes and additional staffing plans.

FAQ — Frequently Asked Questions

1. What is the recommended AQL for custom playing cards?

Recommended AQL depends on buyer tolerance and product tier. Commonly, major defects target 0.65%–1.5% and minor defects 2.5%–4%. Use ANSI/ASQ Z1.4 sampling plans for lot-based acceptance.

2. How do I ensure color accuracy for custom designs?

Provide PANTONE or CMYK targets, request ICC profiles and contract proofs, and perform press checks under standardized lighting (D50). Maintain densitometer readings and a press fingerprint for repeat jobs.

3. Which card stock is best for High Quality decks?

High Quality decks often use clay-coated paperboard or plastic-coated card stock with 300–420 gsm (varies by desired rigidity). Soft-touch lamination or air-cushion coatings are common for tactile performance; request samples to evaluate feel and shuffle behavior.

4. Should I require third-party inspection?

Yes, especially for first orders, high-value SKUs, or new suppliers. Third-party inspection firms provide impartial sampling, defect classification, and pre-shipment verification to reduce dispute risk.

5. How do I handle color differences between batches?

Keep master proofs and press settings documented. Require the supplier to maintain ink lot control and ICC profiles. For multi-batch orders, specify that batches be produced under consistent press conditions or request pre-matched batches.

6. What packaging checks are essential for export?

Verify carton strength, moisture protection (desiccant or shrink-wrap), correct labeling and barcodes, pallet stability, and compliance with shipping regulations. For sea freight, protect against humidity and stacking load.

Contact & Next Steps

Need a supplier audit template, sample QC forms, or a tailored checklist for your custom design playing cards? Contact our team to request a free QC starter pack, sample evaluation, or to view our product and service offerings. Email: sales@example.com | Request a quote: https://www.example.com/contact

References

- ISO 9001 — Quality management systems (accessed 2026-01-12)

- ASQ — Acceptance Sampling (ANSI/ASQ Z1.4 overview) (accessed 2026-01-12)

- Forest Stewardship Council (FSC) — Chain of Custody and responsible sourcing (accessed 2026-01-12)

- The International Playing-Card Society — History and references for card manufacturing (accessed 2026-01-12)

- TAPPI — Paper and board testing standards (accessed 2026-01-12)

Custom chinese playing cards factory Manufacturers and Suppliers in Europe

What are the different types of custom made playing cards manufacturers?

Custom color learning cards Manufacturers and Suppliers in us

Accessibility: Making Custom Cards Inclusive

About customized services

Can I see a proof before production?

Yes! We provide digital proofs for your approval before we start production. This ensures that everything meets your expectations.

Can I customize the design of my cards?

Absolutely! We offer full customization options, from card design and size to finishes and packaging. Our design team is ready to collaborate with you to create the perfect look.

About logistics

How long does the production process take?

Production times can vary based on order complexity and volume. Typically, standard orders take 2-4 weeks. For urgent projects, we may offer expedited options—just ask!

About price and payment

What payment methods do you accept?

We accept various payment methods, including credit cards, PayPal, and bank transfers. Please reach out for more details on payment options.

About cooperation process

How do you ensure the quality of your cards?

We implement strict quality control measures at every stage of production. Our team conducts thorough inspections to ensure each card meets our high standards before shipping.

Board Game Manufacturing Top Quality Custom Logo custom design die cut fancy playing cards profesional card

OEM Custom Driving Theory Cards | Personalized Traffic Rules & Test Prep Flashcards in Multiple Languages for Wholesale

Custom Printing Luxury Two Sets Plastic Poker Playing Cards with Customized Packing

bbilaser

sq_AL