The Ultimate Guide to Custom Design Playing Cards: Master Your Deck in 2026

A comprehensive skyscraper guide on designing and manufacturing custom playing cards. Covers strategic planning, design software, material selection (GSM, finishes), and the manufacturing process. Features expert insights from Guangdong Yuhua Playing Cards Co., Ltd. on professional production standards.

- Introduction: Unlock Your Creativity with Custom Playing Cards

- Phase 1: Concept & Strategic Planning for Your Custom Deck

- Defining Purpose and Audience

- Theme and Brand Identity

- Phase 2: Mastering Design Principles for Playing Card Excellence

- Visual Hierarchy & Readability

- Typography & Color Theory

- Card Back & Packaging

- Phase 3: Choosing Design Software & File Preparation Essentials

- Software Selection

- Dimensions and Safe Zones

- Color Modes: CMYK vs. RGB

- Phase 4: Selecting Card Materials, Stocks & Advanced Finishes

- Understanding GSM and Cores

- Material Sourcing & Sustainability

- Professional Finishes

- Phase 5: The Manufacturing Process: From Prototype to Mass Production

- 1. Prototyping

- 2. Advanced Production

- 3. Quality Control (ISO 9001)

- Phase 6: Printing Options: DIY vs. Professional & Print-on-Demand

- DIY Custom Playing Cards

- Professional Manufacturing

- Phase 7: Budgeting, Timeline & Intellectual Property Considerations

- Beyond Standard Decks: Expanding Your Portfolio with Yuhua

- Partnering with the Right Manufacturer

- Frequently Asked Questions

- What are the standard dimensions for custom playing cards?

- What design software is best for creating custom playing cards?

- How important are bleed, trim, and safe zones in playing card design?

- What types of cardstock and finishes are available for custom playing cards?

- Can I print custom playing cards at home, or should I use a professional manufacturer?

- What is the typical production time for custom playing cards?

- Does Guangdong Yuhua Playing Cards Co., Ltd. handle international orders and shipping?

- What other custom card products does Yuhua specialize in besides playing cards?

- References

Introduction: Unlock Your Creativity with Custom Playing Cards

Whether you are a game developer prototyping a new mechanic, a magician seeking a signature deck, or a brand looking for unique promotional items, custom card printing offers limitless possibilities. In an era where digital content saturates our lives, the tactile experience of a premium deck of cards remains timeless. Personalized playing card design transforms a simple game tool into a piece of art, a learning aid, or a powerful marketing asset.

Creating a professional-grade deck involves more than just slapping a logo on a card back. It requires a deep understanding of design principles, material science, and manufacturing precision. Drawing from the expertise of industry leaders like Guangdong Yuhua Playing Cards Co., Ltd.—a manufacturer with over a decade of experience and a defect rate under 0.5%—this guide will walk you through every step of the journey, from initial concept to the final shuffle.

Phase 1: Concept & Strategic Planning for Your Custom Deck

Before opening any design software, you must define the soul of your deck. Successful custom cards start with a clear purpose.

Defining Purpose and Audience

Are you targeting the tabletop gaming community, which prizes durability and readability? Or is this a collector's item where aesthetics and luxury finishes reign supreme? For educational clients, clarity and engagement are paramount.

Theme and Brand Identity

Consistency is key. Your theme should dictate every design choice, from the font on the Ace of Spades to the texture of the tuck box. Research current trends but strive for a unique visual identity that separates your deck from standard store-bought options.

Phase 2: Mastering Design Principles for Playing Card Excellence

Great design marries form and function. In the world of personalized playing card design, a card must be playable above all else.

Visual Hierarchy & Readability

Players must recognize a card's suit and value instantly. Ensure your pips (the suit symbols) and indices (the numbers/letters in the corners) are distinct. While custom art is encouraged, straying too far from standard conventions can confuse players.

Typography & Color Theory

Select fonts that complement your theme but remain legible at small sizes. Contrast is vital; traditional red and black suits work because they are instantly distinguishable. If you experiment with custom colors, ensure there is high contrast between the background and the indices.

Card Back & Packaging

The card back is the most viewed part of your deck. Symmetrical designs are preferred for gameplay so that a card's orientation doesn't reveal its identity. For the packaging, the tuck box is your first impression. Guangdong Yuhua Playing Cards Co., Ltd. specializes in color-printed packaging that can integrate your branding seamlessly, creating a premium unboxing experience.

Phase 3: Choosing Design Software & File Preparation Essentials

To bridge the gap between your vision and the printing press, you need the right card design software for custom decks and technical know-how.

Software Selection

· Adobe Illustrator: The industry standard for vector graphics, ensuring your lines remain sharp at any size.

· Adobe Photoshop: Ideal for complex, painterly illustrations.

· Canva/GIMP: Accessible alternatives for beginners or those on a budget.

Dimensions and Safe Zones

According to Wikipedia, the standard "Poker size" card measures 2.5 inches by 3.5 inches (63.5 mm x 88.9 mm), while "Bridge size" cards are narrower at 2.25 inches (57 mm) width. When setting up your file, you must account for bleed (usually 0.125 inches or 3mm) which extends the artwork beyond the cut line to prevent white edges.

Color Modes: CMYK vs. RGB

Understanding color is critical. As noted by printing experts at VistaPrint, screens display color in RGB (Red, Green, Blue) using light, while printers use CMYK (Cyan, Magenta, Yellow, Black) ink. You must design in or convert to CMYK to ensure the colors you see on screen match the final printed product. Ignoring this can result in dull or inaccurate colors.

Phase 4: Selecting Card Materials, Stocks & Advanced Finishes

The tactical feel of a card is defined by its paper weight and finish. This is where knowledge of playing card stock and finishes becomes essential.

Understanding GSM and Cores

Paper weight is measured in Grams per Square Meter (GSM). According to PrintNinja, standard card game stock is typically 280gsm to 300gsm, while casino-grade cards often use 310gsm or 330gsm with a black core layer to prevent light from shining through (opacity).

Material Sourcing & Sustainability

Quality starts with the raw material. Yuhua Playing Cards uses premium imported materials and offers FSC® certified options. The Forest Stewardship Council (FSC) certifies that materials are harvested responsibly, protecting biodiversity and workers' rights, which is increasingly important for modern consumers.

Professional Finishes

· Linen Finish: A textured cross-hatch pattern that traps air, allowing for smoother shuffling.

· Spot UV & Foil Stamping: Adds shiny, raised elements to specific parts of the card or box for a luxury feel.

· Plastic Coating: Enhances durability, essential for cards meant for frequent handling.

Phase 5: The Manufacturing Process: From Prototype to Mass Production

Understanding the custom card production process helps you manage expectations and ensure quality. Partnering with a professional playing card manufacturer like Yuhua ensures your project benefits from industrial-scale efficiency.

1. Prototyping

Never skip the prototype. This physical sample allows you to test the card feel, color accuracy, and box fit before committing to thousands of units.

2. Advanced Production

Yuhua operates a 6,000 m² intelligent facility capable of producing over 1,000,000 units per month. This scale is supported by automated lines that handle cutting, collating, and boxing with precision.

3. Quality Control (ISO 9001)

Consistency is the hallmark of professionalism. Yuhua adheres to ISO 9001 standards, a globally recognized quality management system. As outlined by SGS, ISO 9001 principles emphasize "Process Approach" and "Evidence-based Decision Making," which Yuhua leverages to maintain a defect rate of under 0.5%.

Phase 6: Printing Options: DIY vs. Professional & Print-on-Demand

Deciding how to produce your deck depends on your budget and goals.

DIY Custom Playing Cards

For a single prototype or a personal gift, printing at home is an option. However, achieving consistent double-sided alignment and proper corner rounding is notoriously difficult without industrial equipment.

Professional Manufacturing

For game card printing services and commercial releases, professional manufacturing is non-negotiable. Manufacturers like Yuhua offer:

· Scalability: From 500 decks to 1 million.

· Finishing: Access to foil, embossing, and air-cushion textures that DIY cannot replicate.

· Consistency: Every deck is identical, ensuring fair play.

Phase 7: Budgeting, Timeline & Intellectual Property Considerations

· Budgeting: Factor in the cost of high-grade paper (GSM), special finishes, and packaging. Bulk orders significantly reduce the cost per unit.

· Timeline: Production typically takes several weeks. Allow time for file review, digital proofs, physical samples, and shipping.

· Intellectual Property: Protect your work. Yuhua respects client IP and can work under Confidentiality Agreements (NDAs), ensuring your unique designs remain yours.

Beyond Standard Decks: Expanding Your Portfolio with Yuhua

The market for custom cards extends far beyond poker.

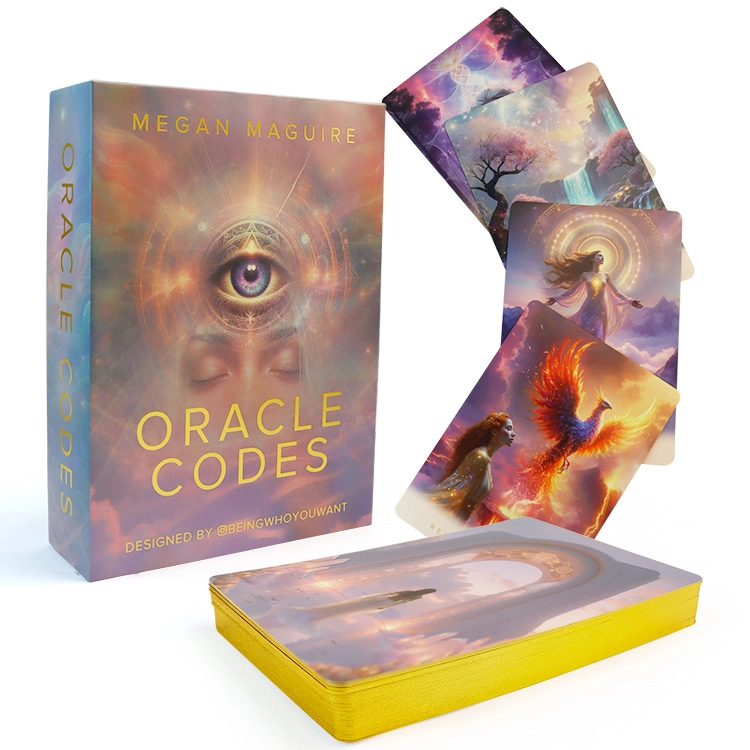

· Custom Tarot Card Printing: Tarot decks often require larger dimensions (e.g., 70mm x 120mm) and thicker stock (350gsm+) to convey luxury and mysticism. Yuhua's ODM services cater specifically to these unique artistic needs.

· Educational Flash Card OEM: Durability is key for learning tools. Yuhua produces robust flashcards designed to withstand the wear and tear of classroom environments.

· Casino-Grade Cards: For environments requiring absolute security and performance, Yuhua provides black-core cards that meet rigorous casino standards.

Partnering with the Right Manufacturer

Choosing the right partner is as critical as the design itself. Guangdong Yuhua Playing Cards Co., Ltd. stands out as a premier choice for global clients.

· Experience: Founded in 2014, with a decade of specialized R&D.

· Innovation: Holding over 20 patents, Yuhua is at the forefront of card manufacturing technology.

· Global Reach: Serving international markets with professional support via sales@ivapoker.com.

· Unwavering Quality: With ISO 9001 certification and a commitment to FSC® standards, Yuhua delivers products that build trust with your end-users.

Frequently Asked Questions

What are the standard dimensions for custom playing cards?

According to industry standards, Poker size cards measure 2.5 x 3.5 inches (63 x 88 mm), while Bridge size cards are slightly narrower at 2.25 x 3.5 inches (57 x 88 mm). Custom dimensions are also available for Tarot or flashcards.

What design software is best for creating custom playing cards?

Adobe Illustrator is the preferred choice for professionals due to its vector capabilities, ensuring crisp text and lines. Photoshop is excellent for detailed artwork. For beginners, Canva offers user-friendly templates, though care must be taken with print bleed settings.

How important are bleed, trim, and safe zones in playing card design?

They are critical. "Bleed" extends artwork 3mm (0.125 inches) beyond the trim line to ensure no white edges appear after cutting. The "Safe Zone" keeps essential text and icons away from the edge to prevent them from being chopped off during the die-cutting process.

What types of cardstock and finishes are available for custom playing cards?

Common options include 300gsm (standard), 310gsm (linen), and 330gsm (casino grade) stocks. Finishes range from standard varnish and UV coating to premium options like gold foil stamping, embossing, and spot UV. Yuhua also offers FSC® certified environmentally friendly materials.

Can I print custom playing cards at home, or should I use a professional manufacturer?

DIY printing is viable for rough prototypes but lacks the durability, snap, and finish of professional cards. For commercial products, a professional manufacturer like Yuhua is essential to ensure consistent quality, proper alignment, and access to advanced finishes like linen texture.

What is the typical production time for custom playing cards?

Production timelines vary by quantity and complexity but generally range from a few weeks to a month after the digital or physical proof is approved. Mass production at facilities like Yuhua's can be expedited due to high-capacity automated lines.

Does Guangdong Yuhua Playing Cards Co., Ltd. handle international orders and shipping?

Yes, Yuhua serves a global market, providing high-quality manufacturing and logistics support for clients worldwide. You can contact them at +86 186 7688 0318 for specific shipping inquiries.

What other custom card products does Yuhua specialize in besides playing cards?

Beyond standard playing cards, Yuhua specializes in ODM Tarot cards, Learning Flash cards OEM, game cards, and board game components, leveraging their 20+ patents to offer unique solutions for various industries.

References

· Wikipedia: Standard 52-card deck

· VistaPrint: RGB vs CMYK: What's the Difference?

The Table Turn Slayer: How Drinking Game Cards Maximize Dwell Time and Revenue for Nightlife Venues

The Scalable Learning & Engagement Library: How Series of Game Cards Revolutionize Corporate Training

Living Lore: From IP to Emotional Ecosystem – How Deity Divination Cards Transform Passive Fans into Active Participants

The Communication Catalyst for High-Performance Teams: How Conversation Cards Structure Meaningful Dialogue

The Corporate Wellness Oracle: How Miniature Tarot Cards Are Revolutionizing Workplace Wellbeing and Team Dynamics

About customized services

Do you offer samples?

Yes! We can provide samples of our card materials and finishes. Please contact us to request samples relevant to your project.

What is the minimum order quantity for Private Label projects?

Our minimum order quantity usually starts at 500 pairs. However, we can handle smaller orders depending on the specific project requirements.

Can I see a proof before production?

Yes! We provide digital proofs for your approval before we start production. This ensures that everything meets your expectations.

Do you provide design services?

Yes! Our in-house design team is here to assist you in bringing your vision to life. Whether you have a complete design or just an idea, we can help.

About price and payment

What are the payment terms?

We require a 30% deposit upon order confirmation and the balance before shipment.

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL