Custom Design Playing Cards: The Ultimate 2026 Guide to Manufacturing and Artistry

- How do you start a custom design playing card project?

- Core Project Steps

- 2026 Design Trends: Beyond the Standard Deck

- Key Industry Shifts

- Technical Specs: Ensuring Professional Playability

- Critical Specifications

- Manufacturing & Distribution Strategy

- Production & Logistics

- Expert Tips: Common Design Pitfalls to Avoid

- Design Safety Checks

- Final Thoughts

- Frequently Asked Questions

- What is the best software for designing custom playing cards?

- What is the standard size for a custom poker deck?

- What is the difference between smooth and linen finishes?

- How many cards are in a standard custom deck?

- Can I print just one single deck of custom cards?

- What is a 'tuck box' in playing card design?

- How do I ensure my custom cards are not see-through?

- What are 'court cards' in a custom deck?

- References

How do you start a custom design playing card project?

To launch a successful custom deck, you must first define your target audience—whether for magic, cardistry, or collecting—then select standard dimensions like poker size card templates and establish a unified visual theme before choosing between digital prototyping or professional offset manufacturing.

Developing a custom deck is more than just placing art on paper; it requires a strategic approach to both aesthetics and mechanics. Start by determining the primary function of the deck. For instance, a deck designed for cardistry requires different handling properties than one meant for a souvenir shop. At Guangdong Yuhua Playing Cards Co., Ltd., we often advise clients to lock in these core decisions early, as they dictate material choices later in the process.

Core Project Steps

- Define Your Concept: Identify if your deck is for high-stakes gameplay, magic performance, or the collector market. This influences whether you need standard faces or fully custom indices.

- Select Dimensions: The industry standard is the Poker size (2.5" x 3.5"), but Bridge size (2.25" x 3.5") is preferred for certain games. Using accurate poker size card templates ensures your artwork fits within the safe zones.

- Establish a Visual Theme: Create a cohesive look that connects your back design, court cards, and pips. Consistency is key to a professional look.

- Choose Production Path: Opt for Print-on-Demand (POD) for single prototypes to test the feel, but move to offset printing for runs of 500+ to achieve cost efficiency and higher quality control.

2026 Design Trends: Beyond the Standard Deck

Leading trends for 2026 focus on eco-luxury materials like FSC-certified stocks and vegetable inks, the integration of generative AI for complex pattern creation, and the rise of "Phygital" decks that use NFC technology to bridge physical cards with digital experiences.

The market for analog gaming is booming. According to a recent report by Research and Markets, the global playing cards and board games market is projected to reach over $22 billion by 2025. To capture this growing audience, designers are moving away from standard plastics toward sustainable luxury. We have seen a significant shift in our own production lines at Yuhua, with more clients requesting biodegradable coatings that do not compromise the slip and snap of the cards.

Key Industry Shifts

- Eco-Luxury Materials: Use of FSC-certified paper from responsible sources and soy-based inks. This appeals to the environmentally conscious collector without sacrificing the premium feel.

- AI-Enhanced Workflows: Designers are utilizing AI tools to generate intricate, symmetrical back designs and unique court card character concepts, speeding up the ideation phase.

- Digital-Physical Hybrids: innovative decks now include NFC chips embedded in the tuck box or specific gaff cards, allowing users to unlock digital tutorials or authentication certificates via smartphone.

- Minimalist Cardistry: A focus on high-contrast geometric patterns that create stunning visual bands during fans and flourishes, prioritizing motion over detailed illustrations.

Technical Specs: Ensuring Professional Playability

Professional playability relies on selecting the correct paper core opacity, applying a performance-grade linen finish cardstock for smooth fanning, and adhering to strict vector formatting to ensure crisp print registration at high speeds.

If a deck looks beautiful but clumps when shuffled, it will fail in the market. The gold standard for handling is often compared to USPCC manufacturing standards, known for their specific "Air-Cushion" feel. To replicate or exceed this, manufacturers like Yuhua utilize advanced embossing rollers that create microscopic air pockets on the card surface.

Critical Specifications

- Paper Stock Hierarchy:

- Professional (M31): High stiffness and snap, ideal for casinos and magic.

- Standard (S30): Good for promotional decks and board games.

- Black Core: Essential for opacity. It prevents light from passing through the card, ensuring opponents cannot see your hand.

- The Importance of Finish: A linen finish cardstock (cross-hatch texture) reduces surface friction, allowing cards to glide evenly. Smooth finishes are often reserved for plastic cards or specific aesthetic preferences.

- Bleeds and Safe Zones: Artwork must extend 3mm beyond the trim line (bleed) to account for cutting tolerance. Vital elements like numbers must stay within the "safe zone" to avoid being chopped off.

- Vector vs. Raster: Text and pips should be vector-based (SVG/EPS) for razor-sharp edges. Raster images (JPEG/PNG) should only be used for complex painted artwork and must be at least 300 DPI.

Manufacturing & Distribution Strategy

Success in manufacturing depends on balancing unit costs with premium additions like custom tuck box printing and foil accents, while leveraging crowdfunding platforms to validate demand before committing to large-scale offset production runs.

Crowdfunding remains a powerhouse for indie creators. Data shows that tabletop game projects on Kickstarter raised over $330 million in 2024, proving that backers are willing to pay a premium for high-quality, unique decks. However, fulfillment is where many projects fail. Partnering with a manufacturer that has robust logistics, like Yuhua's ability to produce 1,000,000+ units per month with a defect rate under 0.5%, ensures that you can deliver on your promises.

Production & Logistics

- Manufacturer Comparison: Evaluate partners based on their ability to handle specialty finishes. While some offer low minimums, professional offset printers provide better consistency for bulk orders.

- Custom Tuck Box Printing: The box is the first thing a buyer sees. Invest in cold foil stamping, embossing, or spot UV on the tuck box to increase perceived value.

- Crowdfunding Strategy: Use platforms like Kickstarter to secure funds for expensive tooling (like metal dies for foiling) before production begins.

- Quality Control: Ensure your manufacturer adheres to ISO 9001 standards. At Yuhua, our intelligent facility automates inspection to catch misprints that the human eye might miss.

Expert Tips: Common Design Pitfalls to Avoid

To prevent costly re-prints, designers must ensure back designs are perfectly 180-degree reversible, avoid heavy ink density on borders to prevent chipping, and prioritize legibility in cardistry deck design over purely abstract art.

Experienced designers know that the physical limitations of cutting machines must be respected. A common issue is the "drift" that occurs during die-cutting. If your design has a 1mm border, a 0.5mm drift will look like a massive error. This is why we recommend wider borders or borderless designs for beginners.

Design Safety Checks

- The 'Symmetry Trap': Test your back design by rotating it 180 degrees. If it is not identical, it is a "one-way" back, which magicians generally avoid unless it is a marked deck feature.

- Thin Border Risks: Avoid extremely thin white borders. Slight shifts in cutting registration can make borders look uneven, ruining the deck's aesthetic.

- Ink Saturation: Deep black cards require careful ink management. Too much ink can make cards sticky or prone to marking (white edges showing) after heavy use.

- Legibility vs. Art: In cardistry deck design, while motion is key, the cards must still be playable. Ensure suit indices are instantly recognizable to avoid confusing players during a game.

-

Final Thoughts

A successful custom playing card project blends artistic vision with mechanical precision and manufacturing expertise. By planning strategically, respecting production constraints, and working with an experienced partner, creators can produce decks that perform flawlessly, resonate with collectors, and stand the test of time.

Frequently Asked Questions

What is the best software for designing custom playing cards?

- Adobe Illustrator: The industry standard for vector-based pips, typography, and layout, ensuring crisp lines at any print size.

- Adobe Photoshop: Preferred for highly detailed, digital painting style court card illustrations.

- Procreate: Excellent for initial sketching and concept art, though files should be vectorized for final print production.

What is the standard size for a custom poker deck?

- Dimensions: The standard poker size is 2.5 inches by 3.5 inches (63.5 x 88.9 mm).

- Corner Radius: Standard decks feature a 3.125-inch corner radius (approx 3mm) for optimal durability and shuffling comfort.

What is the difference between smooth and linen finishes?

- Linen Finish: Features a cross-hatch physical texture that creates air pockets, allowing cards to slide and fan smoothly. This is the preferred finish for magic and handling.

- Smooth Finish: Has a flat, glossy or matte surface. While it can look sleek, it often causes cards to stick together ("clump") due to suction and friction.

How many cards are in a standard custom deck?

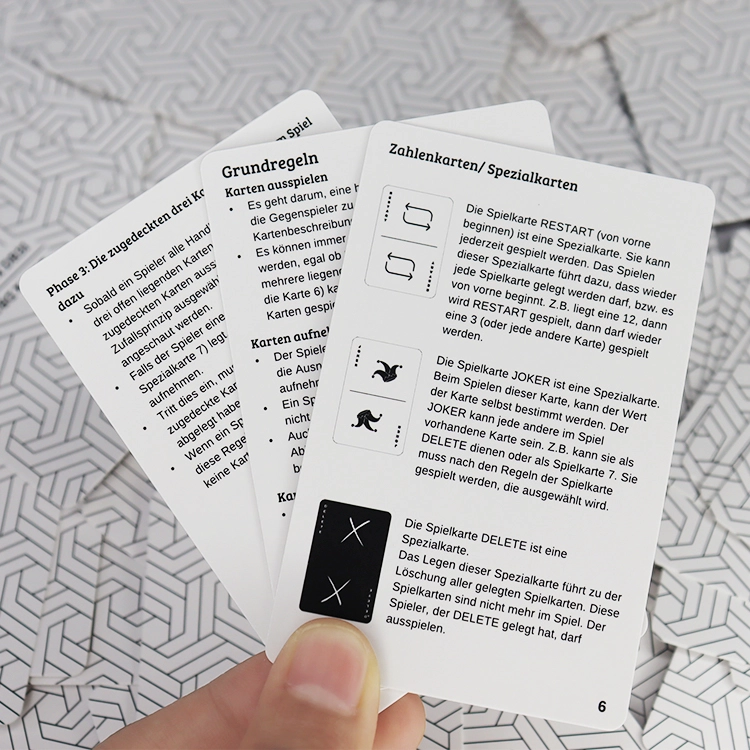

- Standard Count: A deck contains 52 playing cards plus 2 Jokers.

- Printing Sheet: Most offset presses print on sheets that hold 54 or 56 cards. Creators often use the extra 2 slots for ad cards, double-backers, or gaff cards.

Can I print just one single deck of custom cards?

- Prototyping: Yes, services like MPC (MakePlayingCards) offer digital printing with no minimum order quantity (MOQ).

- Bulk Production: For retail quality and lower unit costs, offset printing (starting at 500-1000 decks) is required.

What is a 'tuck box' in playing card design?

- Definition: The tuck box is the outer cardboard packaging that houses the deck.

- Customization: It is a critical branding element, often featuring custom tuck box printing with foil, embossing, and interior printing to attract collectors.

How do I ensure my custom cards are not see-through?

- Core Material: Always request "Black Core" or "Blue Core" cardstock.

- Function: These stocks have an opaque graphite layer sandwiched between the paper sheets to block light.

What are 'court cards' in a custom deck?

- Definition: The Kings, Queens, and Jacks of each suit.

- Design: These are the primary area for artistic expression, often depicting characters relevant to the deck's theme.

References

How to Create Your Own Custom Playing Cards: A Step-by-Step Design Tutorial (2026 Edition)

Beyond KEM: The 10 Best Professional Poker Card Brands You Didn't Know About (2026 Edition)

Double the Impact: The Substantial Two-Deck Custom Playing Card Gift That Demands Attention

The Ultimate Guide to Custom Playing Card Printing in 2026: Professional Techniques & Design

Custom Made Playing Cards: The 2026 Ultimate Guide to Design, Materials, and Manufacturing

About cooperation process

How long does the OEM process take?

The time depends on the complexity of the project, but generally OEM orders take about 6 weeks from design confirmation to delivery.

About product selection

What types of playing cards do you offer?

We offer a wide range of playing cards including standard decks, custom-designed decks, and specialty cards. Whether you need classic poker cards, bridge cards, or custom promotional decks, we have the options to fit your needs.

What materials do you use for your cards?

We use high-quality, durable materials to ensure the best finish and longevity for your cards. Options include standard cardstock, premium finishes, and eco-friendly materials.

About customized services

Can I see a proof before production?

Yes! We provide digital proofs for your approval before we start production. This ensures that everything meets your expectations.

After-sales support

Can I order a sample before placing a formal order?

Yes, we can provide samples for your review. Please contact us to discuss pricing and options for samples.

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL