The Ultimate Guide to Custom Playing Cards: From Design to Delivery

Custom playing cards have become a popular tool for branding, gifts, and entertainment. From promotional decks to personalized game cards, businesses and individuals alike are seeking unique ways to make their card designs stand out. This guide will walk you through the entire process of creating custom playing cards—from concept and design to production and delivery—ensuring your deck looks professional and leaves a lasting impression.

- Why Custom Playing Cards Matter

- Boost Brand Visibility

- Create a Unique Experience

- Ensure High Quality

- Step 1—Concept & Design

- Define Your Purpose

- Choose Design Elements

- Step 2 — Material Selection

- Step 3 — Printing & Production

- Printing Methods

- Special Finishes

- Production Timeline

- Step 4—Quality Control & Finishing

- Step 5—Packaging & Delivery

- Custom Packaging

- Shipping Logistics

- Delivery Timeline

- Tips for Successful Custom Card Projects

- Conclusion

Why Custom Playing Cards Matter

Custom playing cards are more than just gaming tools—they are powerful marketing instruments, collectible keepsakes, and unique corporate gifts. Investing in personalized decks allows businesses and individuals to express creativity, professionalism, and attention to detail. Each deck becomes a tangible reflection of your brand’s identity, helping create memorable and lasting interactions with your audience.

-

Boost Brand Visibility

Custom playing cards featuring your logo, artwork, or brand colors act as miniature ambassadors for your business. Every time a customer, partner, or event participant handles a deck, it reinforces brand recognition and recall. Over time, these consistent visual cues strengthen brand trust and ensure your company stands out in a competitive marketplace.

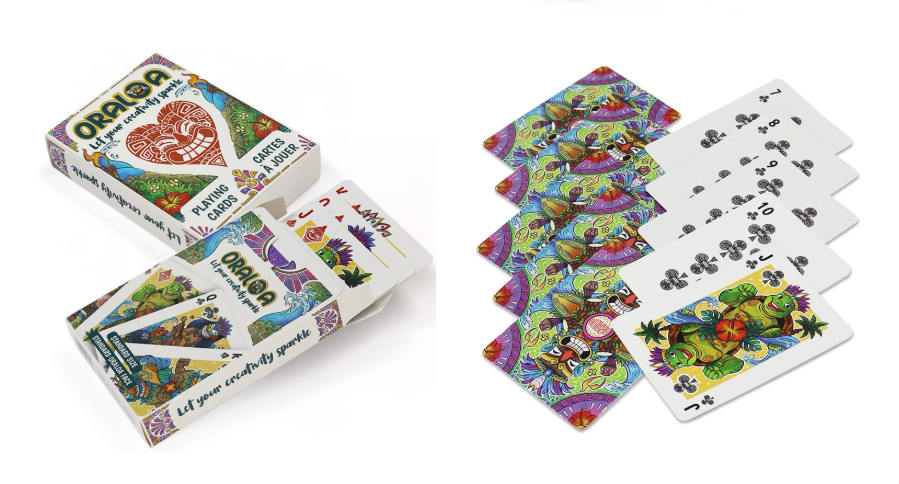

Create a Unique Experience

Decks designed with distinctive illustrations, custom finishes, or thematic concepts provide a one-of-a-kind experience that generic cards simply can’t match. This uniqueness not only increases user engagement but also encourages people to share, photograph, or showcase your deck—effectively generating organic word-of-mouth marketing for your brand.

Ensure High Quality

Working with an experienced OEM playing card manufacturer ensures every deck meets high standards of print precision, durability, and tactile quality. A professionally produced deck conveys reliability and excellence, leaving a lasting impression every time it’s used in games, events, or promotions.

By incorporating custom playing cards into your marketing or product strategy, you elevate your brand image and deliver a high-quality, memorable product that customers will enjoy, keep, and associate with your business for years to come.

Step 1—Concept & Design

The first and most critical step in creating custom playing cards is developing a clear concept and design strategy. A well-planned design ensures your deck looks professional and resonates with your target audience. Thoughtful planning helps prevent costly revisions and maximizes brand impact.

Define Your Purpose

Start by identifying the purpose of your cards—promotional giveaways, corporate gifts, branded merchandise, or gaming decks. Knowing the intended use guides design choices, card size, and packaging options, ensuring your investment delivers maximum value.

Choose Design Elements

Select key design elements that align with your brand and project objectives:

-

Artwork and Illustrations: Original graphics reflecting your brand story. Custom art templates help create distinctive decks.

-

Logos and Branding: Consistent logo placement on cards, boxes, and inserts reinforces brand recognition.

-

Colors and Typography: Match brand colors and maintain readability to ensure a professional, cohesive look.

-

Card Size & Shape: Standard poker size, tarot size, or custom dimensions influence usability and perception of quality.

Thoughtfully combining these elements creates a visually appealing and functional deck that aligns with your brand identity.

Step 2 — Material Selection

Choosing the right materials directly affects durability, feel, and print quality. The following table summarizes the main options:

| Material Type | Features & Benefits | Ideal Use Cases | Link |

|---|---|---|---|

| Paper Cards | PVC coating, matte/gloss finishes, cost-effective, excellent print clarity | Promotional decks, standard game decks | Paper Card Options |

| Plastic Cards | Waterproof, durable, long-lasting, smooth finish | Premium decks, collectible cards, professional games | Plastic Card Options |

| Packaging Options | Paper boxes, metal tins, high-quality plastic cases | Protects cards, enhances presentation, customizable with branding | Packaging Services |

Tips: Match material choice to audience, purpose, and budget. Paper cards suit cost-effective bulk orders, plastic cards are ideal for premium decks. Packaging should reflect the deck’s quality.

Step 3 — Printing & Production

High-quality printing is essential for creating professional and visually appealing custom playing cards. The printing process determines the accuracy of colors, clarity of images, and overall consistency across every deck. Partnering with an experienced OEM playing card manufacturer ensures that your project meets strict quality standards and delivers a polished, high-end result that truly represents your brand.

Printing Methods

Offset Printing:

Ideal for large production runs, offset printing provides vibrant, consistent colors and sharp details. It offers excellent cost efficiency at scale, making it the preferred choice for businesses producing bulk decks for retail or promotional use.

Digital Printing:

Best suited for small to medium batches, digital printing allows for rapid customization and short turnaround times. It’s perfect for limited editions or personalized designs where flexibility and speed are priorities.

Four-Color (CMYK) Printing:

This industry-standard method ensures full-color, detailed image reproduction. CMYK printing enables designers to achieve rich, precise tones and lifelike gradients, resulting in a visually striking final product that stands out from ordinary decks.

Special Finishes

Special finishes elevate your deck’s visual impact and tactile experience. Techniques such as UV coating, hot-foil stamping, spot gloss, and embossing not only enhance the appearance but also improve durability and protection. These premium options add sophistication and depth, making your playing cards feel luxurious and collectible.

Production Timeline

The production process typically ranges from a few weeks to over a month, depending on batch size, design complexity, and finishing requirements. Planning ahead and maintaining open communication with your manufacturer helps prevent delays and ensures timely delivery—especially important for product launches or promotional events.

Step 4—Quality Control & Finishing

-

Inspection:

Each deck undergoes a thorough inspection process to ensure every detail meets high production standards. Checking print alignment, color consistency, and card thickness helps maintain professional quality and guarantees that every deck reflects your brand’s reliability and precision.Trimming and Rounding:

After printing, the cards are precisely trimmed and rounded using advanced cutting equipment. Smooth, even edges not only improve the overall feel but also prevent fraying and wear during long-term use, giving your custom playing cards a refined, premium finish.Finishing Touches:

Special finishing techniques such as lamination, UV coating, and embossing are applied to elevate both durability and visual appeal. These treatments protect the cards from scratches and moisture while enhancing their tactile quality, ensuring your deck looks and feels exceptional even after repeated handling.Sample Testing:

Before full-scale production begins, physical prototypes are carefully reviewed to identify potential design or printing issues. Sample testing allows you to verify colors, materials, and finishes firsthand—reducing risks, avoiding costly reprints, and ensuring the final decks perfectly match your expectations.

Step 5—Packaging & Delivery

-

Custom Packaging

The right packaging not only protects your playing cards but also enhances their perceived value. Options include paper tuck boxes, metal tins, or high-quality plastic cases, each customizable with your logo, color palette, and design elements. Premium packaging transforms your deck into a collectible item and reinforces your brand identity from the very first impression. Explore packaging inspiration and examples on our Custom Playing Cards page.

Shipping Logistics

Efficient logistics ensure that your custom decks arrive safely and on schedule. Depending on your budget, destination, and deadline, you can choose air freight for fast delivery, sea freight for bulk shipments, or express couriers for smaller, time-sensitive orders. Working closely with your OEM partner helps you select the best shipping method, handle customs efficiently, and minimize potential delays.

Delivery Timeline

Production and shipping timelines vary depending on your order volume, design complexity, and destination. It’s essential to communicate clearly with your OEM partner to confirm estimated lead times and coordinate final delivery schedules. Most standard orders are completed within a few weeks, while customized projects may require additional time for special finishes or packaging.

Tips for Successful Custom Card Projects

-

Plan Ahead: Organize your design, production, and delivery timelines early to avoid last-minute stress.

-

Maintain Clear Communication: Regular updates with your OEM manufacturer ensure smooth coordination from design approval to shipment.

-

Start with a Sample Batch: Ordering a small prototype run helps verify print quality, finishes, and packaging before scaling up production.

-

Research Market Trends: Stay updated on popular themes, finishes, and card designs to align your deck with customer preferences.

-

Align with Brand Identity: Choose materials, finishes, and packaging styles that reflect your brand’s personality and message, ensuring consistency across all marketing channels.

Conclusion

Creating custom playing cards—from concept and design to printing, packaging, and delivery—is a meticulous process that combines creativity, precision, and craftsmanship. By collaborating with an experienced OEM playing card manufacturer, you can ensure that every deck reflects your brand’s identity and meets the highest quality standards. Whether you’re designing decks for corporate promotions, retail sales, or collector editions, a professional partner helps transform your vision into reality.

Call to Action: Contact IVA Poker today for a free consultation and custom quote. Our expert team will guide you through design, printing, and packaging options to create premium playing cards that perfectly match your brand vision.

How to Create Your Own Custom Playing Cards: A Step-by-Step Design Tutorial (2026 Edition)

Beyond KEM: The 10 Best Professional Poker Card Brands You Didn't Know About (2026 Edition)

Custom Design Playing Cards: The Ultimate 2026 Guide to Manufacturing and Artistry

Double the Impact: The Substantial Two-Deck Custom Playing Card Gift That Demands Attention

The Ultimate Guide to Custom Playing Card Printing in 2026: Professional Techniques & Design

About product selection

What materials do you use for your cards?

We use high-quality, durable materials to ensure the best finish and longevity for your cards. Options include standard cardstock, premium finishes, and eco-friendly materials.

About price and payment

What are the payment terms?

We require a 30% deposit upon order confirmation and the balance before shipment.

After-sales support

What is your return policy?

We stand behind the quality of our products. If you receive a defective item, please contact us within 30 days for a replacement or refund. Customized orders are generally non-refundable unless there's an error on our part.

Can I order a sample before placing a formal order?

Yes, we can provide samples for your review. Please contact us to discuss pricing and options for samples.

About customized services

What is the minimum order quantity for Private Label projects?

Our minimum order quantity usually starts at 500 pairs. However, we can handle smaller orders depending on the specific project requirements.

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL