How to Choose the Right Paper Box Material for Your Product? Comprehensive Analysis of Thickness and Hardness

Choosing the right paper box material is crucial for product packaging, as it affects durability, aesthetics, and cost. With various options available—such as cardboard, corrugated fiberboard, and art paper—selecting the best material depends on factors like product weight, protection needs, and branding requirements.

This guide provides a comprehensive analysis of paper box thickness and hardness, helping businesses make informed decisions for their packaging needs.

- 1. Understanding Paper Box Materials

- A. Cardboard (Paperboard)

- B. Corrugated Fiberboard (Fluted Cardboard)

- C. Chipboard (Grayboard)

- D. Kraft Paper

- 2. How Thickness Affects Performance

- 3. Hardness and Durability Factors

- A. Rigidity (Bending Resistance)

- B. Compression Strength

- C. Impact Resistance

- 4. How to Choose the Best Material for Your Product?

- Conclusion

1. Understanding Paper Box Materials

Before selecting a material, it's essential to know the common types used in packaging:

A. Cardboard (Paperboard)

-

Thickness: 0.25mm – 1.5mm

-

Hardness: Medium (rigid but not crush-proof)

-

Best for: Cosmetic boxes, food packaging, retail boxes

-

Pros: Lightweight, printable, cost-effective

-

Cons: Not suitable for heavy items

B. Corrugated Fiberboard (Fluted Cardboard)

-

Thickness: 1.5mm – 10mm (varies based on flute size)

-

Hardness: High (excellent shock absorption)

-

Best for: Shipping boxes, electronics, fragile items

-

Pros: Durable, lightweight, customizable

-

Cons: Less premium look compared to solid cardboard

C. Chipboard (Grayboard)

-

Thickness: 1mm – 3mm

-

Hardness: Medium to high (sturdy but not flexible)

-

Best for: Book covers, rigid gift boxes

-

Pros: Eco-friendly, strong structure

-

Cons: Limited printability

D. Kraft Paper

-

Thickness: 0.1mm – 0.5mm

-

Hardness: Low (flexible and foldable)

-

Best for: Eco-friendly packaging, mailing envelopes

-

Pros: Recyclable, rustic aesthetic

-

Cons: Less protective for heavy products

-

2. How Thickness Affects Performance

The thickness (measured in GSM – grams per square meter or microns) determines durability:

Material Thickness Range Ideal Use Case Thin (150-300 GSM) 0.15mm – 0.3mm Lightweight retail boxes (e.g., cosmetics) Medium (300-500 GSM) 0.3mm – 0.5mm Gift boxes, electronics packaging Thick (500-1000+ GSM) 0.5mm – 1mm+ Luxury packaging, heavy-duty shipping Key Considerations:

-

Heavier products require thicker materials (e.g., corrugated board for shipping).

-

Luxury brands may opt for thick, rigid paperboard for a premium feel.

-

Cost efficiency: Thicker materials increase production costs.

-

3. Hardness and Durability Factors

Hardness depends on material composition and structure:

A. Rigidity (Bending Resistance)

-

High rigidity: Chipboard, thick cardboard (best for structured boxes).

-

Low rigidity: Kraft paper (better for flexible packaging).

B. Compression Strength

-

Corrugated board excels in stacking strength (ideal for shipping).

-

Solid bleached sulfate (SBS) board offers a balance between stiffness and print quality.

C. Impact Resistance

-

Fluted corrugation provides cushioning for fragile items.

-

Double-walled cardboard enhances protection for heavy goods.

-

4. How to Choose the Best Material for Your Product?

Follow these steps:

-

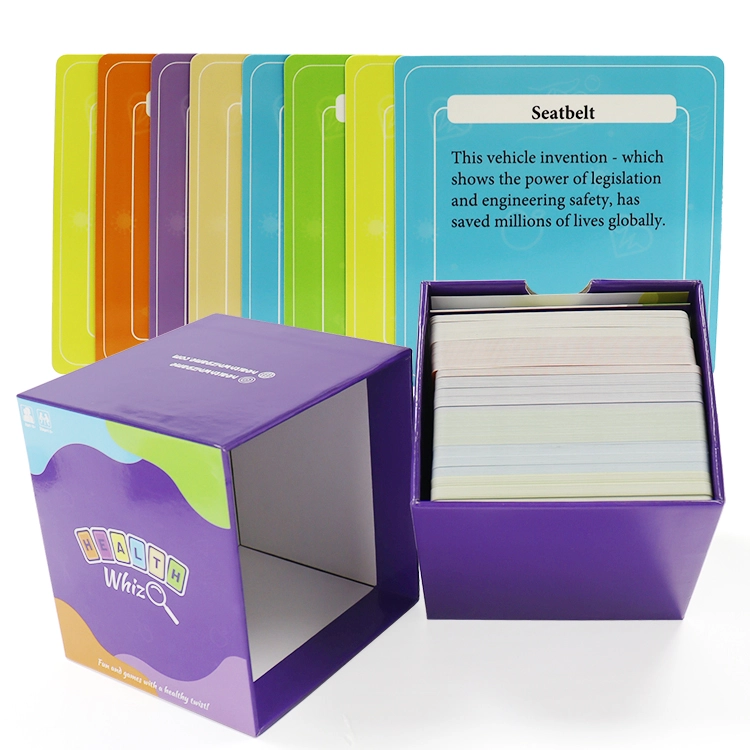

Assess Product Weight & Fragility

-

Light items (e.g., jewelry, cosmetics) → Cardboard (300-400 GSM)

-

Heavy/fragile items (e.g., electronics, glass) → Corrugated board (E or B flute)

-

-

Consider Branding Needs

-

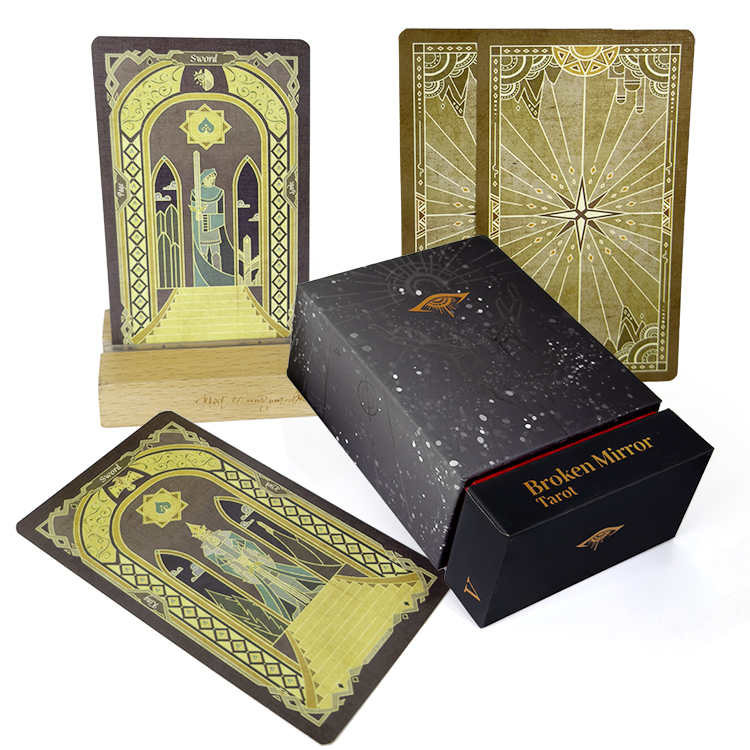

High-end products → Thick, coated paperboard (500+ GSM)

-

Eco-friendly brands → Kraft paper or recycled cardboard

-

-

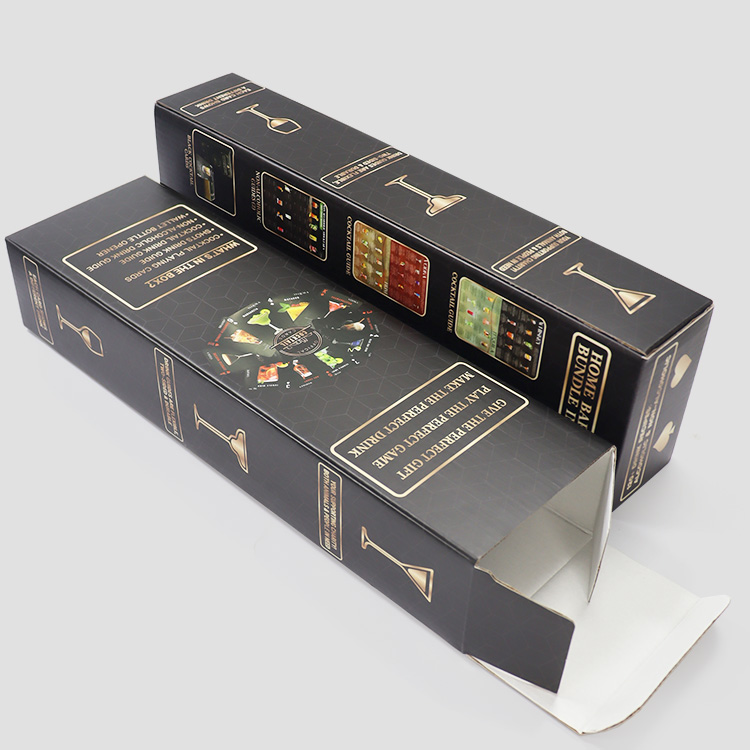

Evaluate Shipping Conditions

-

Long-distance shipping → Corrugated with cushioning

-

Retail display → Sleek, printed paperboard

-

-

Budget Constraints

-

Low-cost options → Standard cardboard or single-wall corrugated

-

Premium packaging → Rigid box with special finishes (foil stamping, embossing)

-

Conclusion

Selecting the right paper box material involves balancing thickness, hardness, cost, and branding needs. By understanding the differences between cardboard, corrugated, chipboard, and kraft paper, businesses can optimize packaging for protection, aesthetics, and sustainability.

For best results, consult with a custom packaging supplier to test materials before mass production.

-

-

-

-

How to Create Your Own Custom Playing Cards: A Step-by-Step Design Tutorial (2026 Edition)

Beyond KEM: The 10 Best Professional Poker Card Brands You Didn't Know About (2026 Edition)

Custom Design Playing Cards: The Ultimate 2026 Guide to Manufacturing and Artistry

Double the Impact: The Substantial Two-Deck Custom Playing Card Gift That Demands Attention

The Ultimate Guide to Custom Playing Card Printing in 2026: Professional Techniques & Design

About product selection

What types of playing cards do you offer?

We offer a wide range of playing cards including standard decks, custom-designed decks, and specialty cards. Whether you need classic poker cards, bridge cards, or custom promotional decks, we have the options to fit your needs.

Can I see a sample before a full order?

Yes, we will provide a prototype sample for your review to ensure you are satisfied with the final product.

After-sales support

Can I order a sample before placing a formal order?

Yes, we can provide samples for your review. Please contact us to discuss pricing and options for samples.

About customized services

Can I see a proof before production?

Yes! We provide digital proofs for your approval before we start production. This ensures that everything meets your expectations.

About logistics

How long does the production process take?

Production times can vary based on order complexity and volume. Typically, standard orders take 2-4 weeks. For urgent projects, we may offer expedited options—just ask!

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL