How to Pick the Best Custom Plastic Playing Cards for Poker

- Understanding Custom Plastic Playing Cards

- What Makes Plastic Playing Cards Different from Paper Ones

- Why Poker Players Prefer Plastic Over Traditional Cards

- Key Features to Look for in the Best Custom Plastic Playing Cards

- Card Material and Durability

- Printing Quality and Color Accuracy

- Waterproof and Easy-to-Clean Design

- Texture, Flexibility, and Handling Performance

- Customization Options for Poker Enthusiasts

- Personalized Designs and Logos

- Choosing the Right Card Finish: Matte vs. Glossy

- Custom Packaging for a Professional Look

- How Printing Quality Impacts Your Poker Experience

- High-Quality Custom Plastic Playing Cards Printing Techniques

- Balancing Affordability and Professional-Grade Results

- Comparing Different Types of Plastic Cards

- 100% PVC vs. PET vs. Composite Plastic Cards

- Which Material Offers the Best Balance Between Price and Performance

- Finding the Right Manufacturer for Your Custom Plastic Playing Cards

- What to Expect from a Professional Poker Card Supplier

- Questions to Ask Before Placing a Bulk Order

- How to Ensure Quality Consistency in Large Orders

- Yuhua – Your Trusted Partner for Premium Custom Plastic Playing Cards

- Final Tips: Making the Smart Choice for Your Poker Nights

Understanding Custom Plastic Playing Cards

The custom plastic playing cards Before deciding on the ideal poker deck, it is essential to know what they are and why they have turned out to be the standard of the gold rush among the amateurs and professionals alike.

PVC or PET are the best materials that are used in manufacturing plastic playing cards. These substances render the cards strong against bending, creasing or tearing that is common with paper decks. Their polished surface makes them easy to shuffle and professional to the touch which experienced players will enjoy.

What Makes Plastic Playing Cards Different from Paper Ones

Paper cards are relatively cheap especially when used frequently since they are easily worn out. They are easily absorbent, easily distorted, and do not have the vibrancy of color. Long lasting plastic playing cards, however, are designed to play thousands of games and not to wear out. They are also cost-effective in the long term as they are very long lasting especially in poker clubs, bars, and gambling establishments.

Why Poker Players Prefer Plastic Over Traditional Cards

Amateurs of poker give preference to consistency and emotion. Plastic cards have standard thickness and flexibility which enables easy dealing, and proper handling. The waterproof plastic playing cards do not spill or form stains, thus they will remain clean and crisp after extended use, which is essential when it is time to play poker in a tournament or high-stakes game.

Key Features to Look for in the Best Custom Plastic Playing Cards

When you have settled on using plastic cards, your next task is to learn what makes the best custom plastic playing cards. In addition to the appearance, printing, and feel, the real quality of it is the choice of material, precision in production and finish of the surface.

Card Material and Durability

When durability of the cards is the priority then look 100 percent PVC cards. PVC has very good flexibility and impact resistance such that the cards spring back to their shape after bending. PVC decks are also glossy unlike composite cards which are made up of a paper core and they are not water resistant. To the frequent players of poker, it translates to less replacement and a much easier game to play- thus providing them a great long term value.

Printing Quality and Color Accuracy

The popularity of the custom plastic playing cards printing is connected to the brightness and sharpness of the designs. The UV or offset printing technology offers high resolution so that all the faces of the card, the symbols of the suits, and any logo that the company has developed are clear and even. The inks used are of professional grade, so the color will not fade once hundreds of hands have been dealt.

Waterproof and Easy-to-Clean Design

The waterproof coating of plastic cards is perfect when visiting a bar, club, or poker in a pool. Fingerprints or spills can be removed by simply wiping out, and this will help to keep them fresh-out-of-the-box looking. It is a basic yet indispensable attribute that contributes a lot to the usability and hygiene of the cards.

Texture, Flexibility, and Handling Performance

The high-end plastic cards are designed to offer optimum slickness and grip. They are easy to shuffle and do not attach themselves and evenly spread on any surface. To the players, this reliable handling is what develops a trust in the quality of the deck, which can be done with cheap custom plastic playing cards by a trusted company.

Customization Options for Poker Enthusiasts

The area that custom plastic playing cards shine is customization. Other than performance they provide a branding experience to casinos, clubs and companies interested in making a long lasting impact.

Personalized Designs and Logos

In the current day, you can make customized plastic playing cards of logo in practically any form. Custom designs will give you a unique touch whether it is your casino logo, company logo or tournament logo. This will make your deck not only a gaming tool, but also a brand ambassador, which is who you are and how professional you are.

Choosing the Right Card Finish: Matte vs. Glossy

The card finish has an impact on both appearance and the game play. Matte finishes also have a light texture, which brings out better control and glare minimization - perfect in a well-lit poker room. On the contrary, glossy finishes provide a high quality appearance which has high color contrast and can be used in promotional or luxury themed decks. The selection of appropriate finish is dependent on the purpose of usage of the cards.

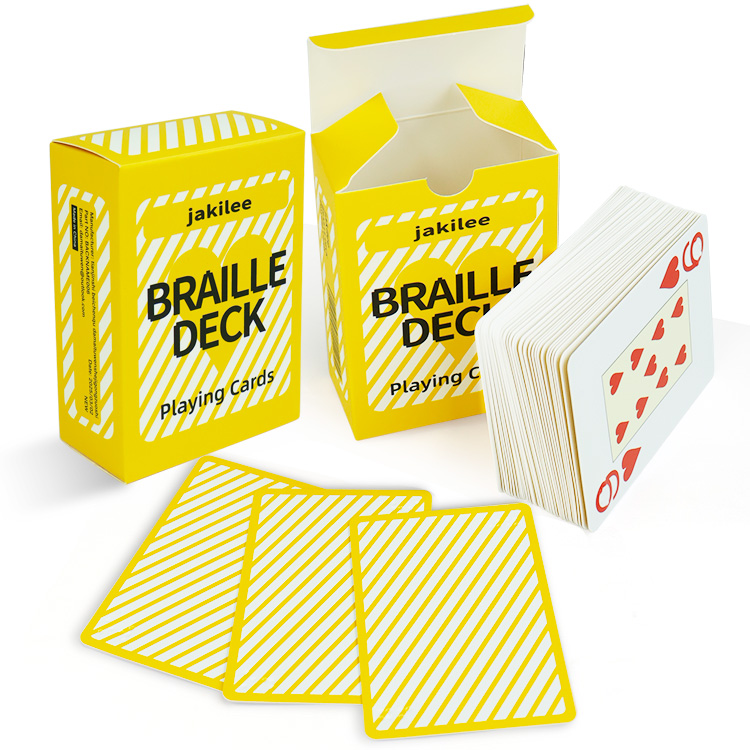

Custom Packaging for a Professional Look

The premium cards should be packed with a premium touch. A custom box- whether it is a magnetic closure box, a clear-plastic box or a branded tuck box- is not only a protection to your cards, but it also enhances brand presentation. Businesses tend to give out promotions through branded plastic playing cards accompanied with appropriate packaging that supports the visual consistency.

How Printing Quality Impacts Your Poker Experience

Printing quality is not needed to have a nice appearance, but to ensure a smooth user experience. The edge of each side of cards and the endurance of the design are directly related to the game play.

High-Quality Custom Plastic Playing Cards Printing Techniques

The manufacturers at the highest tier employ the use of hi-tech UV printing and lamination methods to create bright and smudge-proof graphics. The cards are printed so precisely that they are microscopic in order to make them have perfect edges and align perfectly. What it brings about is a deck that appears and feels high quality even after unleashing 100 games.

Balancing Affordability and Professional-Grade Results

The legend that the premium cards are necessarily costly is obsolete. Modern printing methods allow one to print out cheap playing cards made of plastic, and play as well as other high-quality cards in the casino. The trick is to maximize sourcing of materials and bulk production - doing it without compromising.

Comparing Different Types of Plastic Cards

Knowing the distinction between plastic materials would enable you to select the right deck, depending on the use and budget.

100% PVC vs. PET vs. Composite Plastic Cards

- PVC (Polyvinyl Chloride) – Offers top-tier flexibility, water resistance, and durability. Ideal for professional poker environments.

- PET (Polyethylene Terephthalate) – A slightly stiffer and more eco-conscious material that performs well in moderate-use settings.

- Composite Plastic Cards – Combine a paper core with a plastic outer layer, offering a balance between texture and cost.

In the case of casinos and professional poker rooms, PVC is the standard because it has a very high staying capacity and capability to carry high definition prints.

Which Material Offers the Best Balance Between Price and Performance

In case you want to have a dependable product, which works well without going out of your budget, 100 percent PVC cards obtained through a reputable wholesaler of plastic playing cards will present the most optimal ROI as far as the investment is concerned. They are a good investment in small clubs as well as casinos with high scale because of their longevity and quality that is always high.

Finding the Right Manufacturer for Your Custom Plastic Playing Cards

Selecting the most appropriate manufacturer is just as significant as selecting the most appropriate material. A professional partner guarantees the quality, accuracy in printing and delivery on time - all that is necessary to establish your brand reputation.

What to Expect from a Professional Poker Card Supplier

The supplier is supposed to be reputable, and this should also offer full customization assistance, including reviewing artwork and samples of proofs. They should also employ industry grade printing systems and stringent quality control measures to ensure that all batches have one and the same quality.

Questions to Ask Before Placing a Bulk Order

Make sure to clarify all details prior to placing the order: minimum order quantity, method of printing, lead time and packaging options. Knowing these factors will help you set out what to expect based on the ability to produce and prevent the need to make costly changes at a later date.

How to Ensure Quality Consistency in Large Orders

Identify suppliers that are ISO certified and are equipped with modern printing facilities, experience in dealing with international customers. The clear communication and sample endorsement phases are the major signs of the trustworthiness of a manufacturer.

Yuhua – Your Trusted Partner for Premium Custom Plastic Playing Cards

In the manufacture of the finest custom plastic playing cards to play poker, Yuhua can be said to be a leader in quality, technology and expertise in customization. Yuhua was founded in 2008 and its 6,000㎡ smart factory is supplied with the newest German printing equipment and automated production lines. The company has worked with more than 3,000 customers in the world; providing the end-to-end services, such as design, manufacturing, packaged, and delivered to the world.

The low cost of Yuhua custom plastic playing cards manufactured include high accuracy printing, hardwearing plastic PVC materials, and sharp reproduction of colors, - which guarantee that every deck plays perfectly even during stress. Personalized flexibility and predictable quality combine with the ability to customize and offer flexibility contributes to the popularity of the brand whether it is a professional casino, branded events or a personal collection, Yuhua offers it all.

Final Tips: Making the Smart Choice for Your Poker Nights

Balance is all when it comes to choosing the most superior custom plastic playing cards. Give attention to the feel and flexibility and the quality of print along with your budget and intended purpose. Another advantage of premium plastic cards is that they are not only raising your poker nights but also a long-term investment in your fashion, performance, and durability.

Ready to design your own high end poker cards? Furnish Yuhua with a deck that is as professional as your game. The site: https://www.ivapoker.com/, visit Yuhua is where one can start his/her custom order and find the ideal mix of craftsmanship, performance, and cost.

How to Create Your Own Custom Playing Cards: A Step-by-Step Design Tutorial (2026 Edition)

Beyond KEM: The 10 Best Professional Poker Card Brands You Didn't Know About (2026 Edition)

Custom Design Playing Cards: The Ultimate 2026 Guide to Manufacturing and Artistry

Double the Impact: The Substantial Two-Deck Custom Playing Card Gift That Demands Attention

The Ultimate Guide to Custom Playing Card Printing in 2026: Professional Techniques & Design

About cooperation process

How do you ensure the quality of your cards?

We implement strict quality control measures at every stage of production. Our team conducts thorough inspections to ensure each card meets our high standards before shipping.

About logistics

Can you handle shipping and fulfillment?

Yes! We offer comprehensive fulfillment services, including storage, packing, and shipping. You can rely on us to ensure your cards reach their destination safely and on time.

About product selection

What types of playing cards do you offer?

We offer a wide range of playing cards including standard decks, custom-designed decks, and specialty cards. Whether you need classic poker cards, bridge cards, or custom promotional decks, we have the options to fit your needs.

About customized services

What is the minimum order quantity?

We do not have a strict minimum order quantity. Since we are a custom offset printing company, we recommend a minimum order of 500 sets, as the material costs are the same, but the printing setup costs are higher.

However, if your order quantity is less than 300 sets, our sales team will usually work with customers to help customers find the most competitive options.

About price and payment

What are the payment terms?

We require a 30% deposit upon order confirmation and the balance before shipment.

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL