Why Do Your Plastic Signs Fade? UV Coating vs. Lamination vs. Screen Printing

Plastic signs are widely used for branding, advertising, and decoration, but many suffer from premature fading. The key to long-lasting vibrancy lies in choosing the right surface finishing technique. This article explores UV coating, lamination, and screen printing, comparing their durability, cost, and suitability to help you make an informed decision.

Why Do Plastic Signs Fade?

Plastic signs fade due to:

-

UV exposure (sunlight breaks down pigments)

-

Chemical wear (cleaning agents, pollution)

-

Poor surface protection (ineffective coatings)

The right surface treatment can significantly extend a sign’s lifespan. Below, we analyze three popular methods.

1. UV Coating: High Gloss & Moderate Protection

How It Works

A liquid coating is applied and cured instantly using ultraviolet light, creating a hard, glossy layer.

Pros:

✔ Fast drying – Immediate curing reduces production time.

✔ Scratch-resistant – Provides a durable surface.

✔ Enhances colors – Adds a glossy or matte finish.

Cons:

✖ Limited UV resistance – Prolonged sun exposure can still cause fading.

✖ Not flexible – May crack on bendable plastics.

Best for: Indoor signs, short-term outdoor use.

2. Lamination (Film Overlay): Maximum Durability

How It Works

A thin plastic film is heat-sealed onto the sign’s surface, offering an extra protective layer.

Pros:

✔ Superior UV protection – Blocks up to 99% of harmful rays.

✔ Waterproof & chemical-resistant – Ideal for harsh environments.

✔ Textured options – Matte, gloss, or anti-glare finishes available.

Cons:

✖ Higher cost – More expensive than UV coating.

✖ Thicker feel – May not suit ultra-thin designs.

Best for: Outdoor signs, long-term branding.

3. Screen Printing: Traditional but Limited

How It Works

Ink is pressed through a mesh stencil onto the plastic, layer by layer.

Pros:

✔ Vibrant colors – Excellent opacity for bold designs.

✔ Cost-effective for bulk orders – Lower per-unit price.

Cons:

✖ Poor UV resistance – Prone to fading without additional coatings.

✖ Not scratch-proof – Vulnerable to wear and tear.

Best for: Short-term indoor signage, promotional items.

Which Technique Should You Choose?

| Factor | UV Coating | Lamination | Screen Printing |

|---|---|---|---|

| Durability | Medium | High | Low |

| UV Resistance | Moderate | Excellent | Poor |

| Cost | Affordable | Premium | Budget-friendly |

| Best Use | Indoor signs | Outdoor signs | Temporary displays |

For long-lasting outdoor signs, lamination is the best choice. UV coating works well for indoor displays needing a glossy finish, while screen printing is ideal for low-cost, short-term applications.

Conclusion

Fading plastic signs can hurt your brand’s image and increase replacement costs. By selecting the right surface treatment—UV coating, lamination, or screen printing—you can ensure vibrant, durable signage. For outdoor use, lamination provides the best protection, while UV coating balances cost and quality for indoor displays.

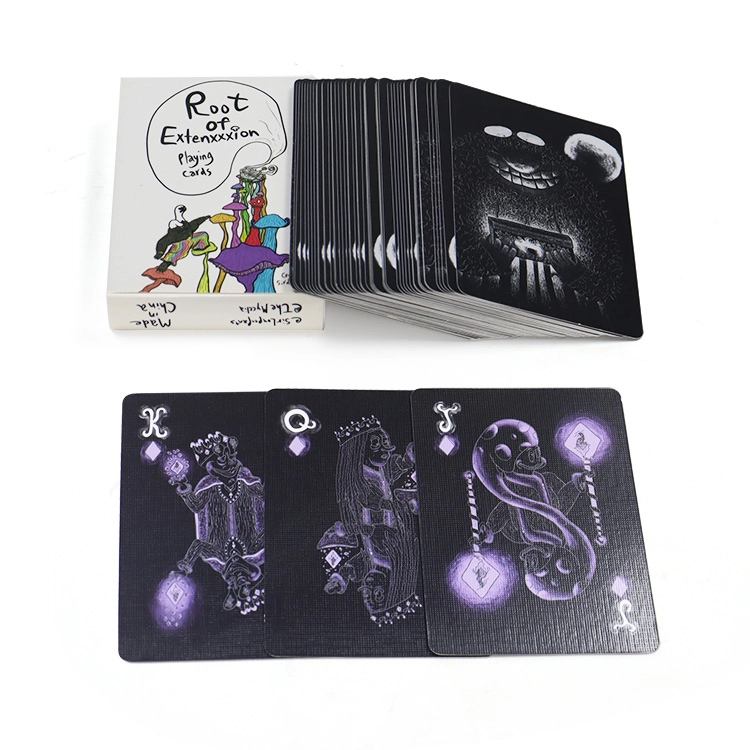

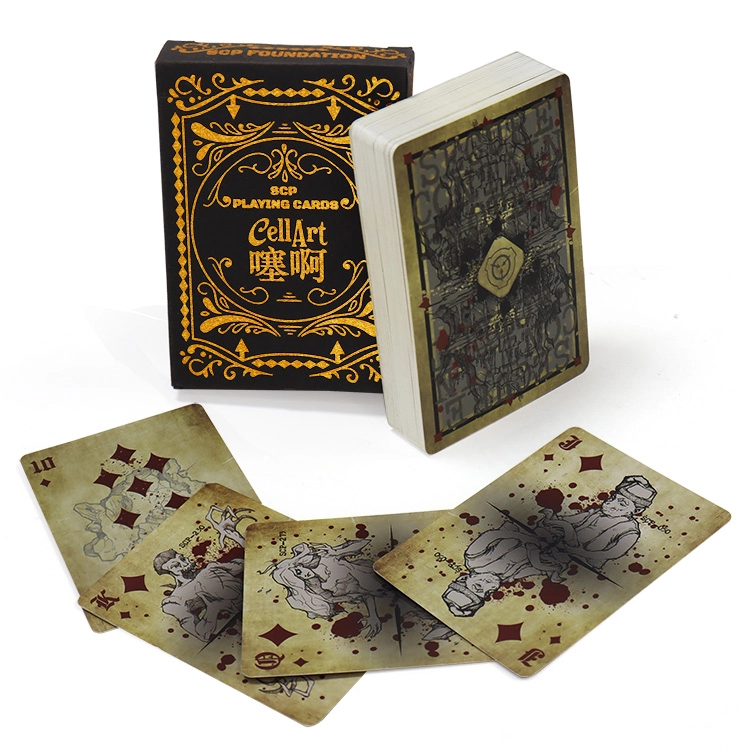

How to Create Your Own Custom Playing Cards: A Step-by-Step Design Tutorial (2026 Edition)

Beyond KEM: The 10 Best Professional Poker Card Brands You Didn't Know About (2026 Edition)

Custom Design Playing Cards: The Ultimate 2026 Guide to Manufacturing and Artistry

Double the Impact: The Substantial Two-Deck Custom Playing Card Gift That Demands Attention

The Ultimate Guide to Custom Playing Card Printing in 2026: Professional Techniques & Design

About product selection

What types of playing cards do you offer?

We offer a wide range of playing cards including standard decks, custom-designed decks, and specialty cards. Whether you need classic poker cards, bridge cards, or custom promotional decks, we have the options to fit your needs.

About customized services

Can I see a proof before production?

Yes! We provide digital proofs for your approval before we start production. This ensures that everything meets your expectations.

Can I customize the design of my cards?

Absolutely! We offer full customization options, from card design and size to finishes and packaging. Our design team is ready to collaborate with you to create the perfect look.

About price and payment

How can I get a quote?

Getting a quote is easy! Simply fill out our contact form or call us directly with your project details, and we’ll get back to you with a tailored quote promptly.

About cooperation process

How do you ensure the quality of your cards?

We implement strict quality control measures at every stage of production. Our team conducts thorough inspections to ensure each card meets our high standards before shipping.

WE’D LOVE TO

FROM YOU

Please send us your inquiry details; our team will contact you ASAP.

20+ years of experience in custom playing cards, game cards, tarot cards, flashcards, and board games, as well as paper and paperboard box manufacturing.

bbilaser

sq_AL